Best Practices for Building a Tech Pack

Streamline communication with your OEM/ODM manufacturer to save time and minimize errors.

When working with an OEM backpack or outerwear manufacturer, such as Kowide Outdoors, one of the most essential information packets you can provide is a comprehensive, well-prepared tech pack. A clear tech pack minimizes misunderstandings, shortens sampling time, and reduces unnecessary back-and-forth communication, enabling your manufacturer to deliver precisely what you need more efficiently.

Below, we will outline the best practices for creating a tech pack that sets your project up for success, based on what we have found to help most of our clients. It’s important to note that these points are best practices—not hard-set rules. Even if you can’t implement every detail mentioned here, a good manufacturer will still be able to interpret your needs and deliver the correct product.

1. Start with a Clear Product Overview

Your tech pack should open with a simple product description. This sets the foundation for everything else. Include:

Style name/number – A unique identifier for easy reference.

Product category – Backpack, duffel, jacket, parka, etc.

Target market and use case – Everyday commuter bag, technical hiking pack, lightweight travel shell, etc.

This quick snapshot enables your manufacturer to immediately understand the product’s purpose and performance expectations, allowing them to kickstart the process with key steps such as assigning the right staff members and preparing the sourcing department.

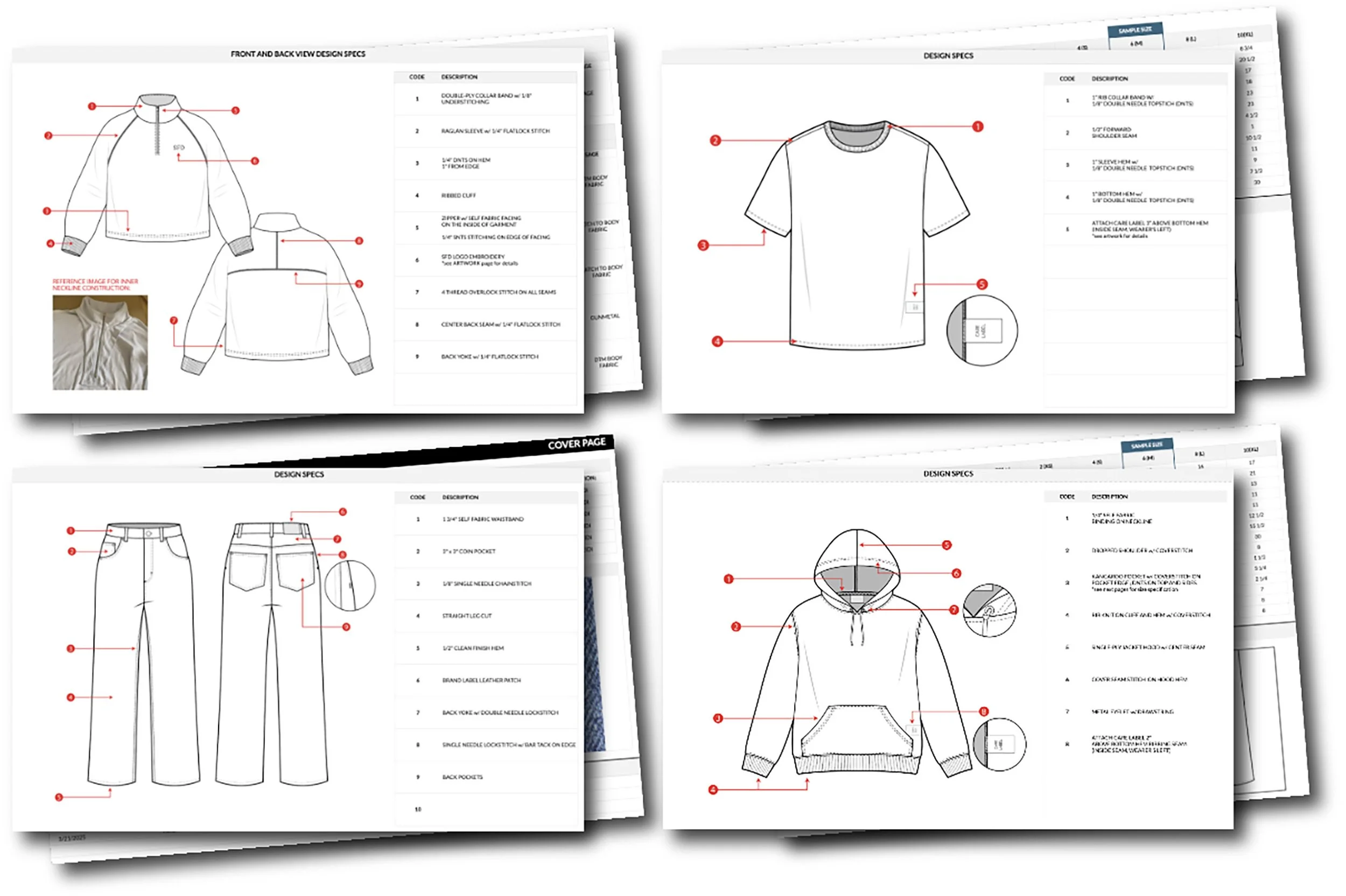

2. Provide Detailed Technical Drawings

Flat sketches (2D line drawings) or CAD renderings should illustrate the product from front, back, side, and inside views.

Keep drawings clean and clear, showing seam placements, pocket locations, straps, or closures.

Label all design features (e.g., “zippered side pocket,” “mesh back panel,” “storm flap”).

Avoid artistic shading—focus on technical clarity.

Be sure to clarify with your manufacturer what type of files they can handle or would prefer. The exact type of drawings can depend on product type and manufacturing processes.

3. Using Reference Samples and Competitor Products

Sometimes, the fastest way to communicate your vision is by referencing an existing sample or product. This can serve as a strong starting point for your manufacturer.

Send your sample to your manufacturer.

Note: Many manufacturers will request permission to inspect the sample by cutting it to verify the fabric and manufacturing processes used to produce it.

Take clear, well-lit photos of the product from multiple angles.

Annotate the photos with detailed notes explaining what you want to keep and what you want to change.

Example: “Keep pocket placement but increase zipper size for durability.”

Example: “Adjust shoulder strap angle for better ergonomics.”

Highlight specific construction details that inspire you (stitching, reinforcements, finishing).

Point out changes in size, materials, or features so your manufacturer understands where your design will differ.

This approach works exceptionally well if you don’t yet have full technical drawings; your annotated photos can guide the technical design process and save time in early communication.

4. Specify Materials and Fabrics Clearly

Backpacks and outerwear rely heavily on the right material selection. A well-prepared tech pack should list:

Main fabrics (e.g., 600D polyester PU x 2, 420D Ripstop RPET nylon).

Lining materials (e.g.,200D polyester, 150g mesh, etc.).

Trims and hardware (zippers, buckles, webbing, snaps).

Note: best practice is to have the hardware labeled with its specific item number (e.g., YKK #8 RC zipper). Or at the very least, if brand and item code are not available, then the desired size. (e.g., for zippers: #8, #5, etc. For buckles: 25mm, 35mm, etc. For webbing: nylon webbing, pp webbing, poly webbing with or without pattern, and size, etc.)

Performance requirements (water resistance rating, tear strength, breathability, etc.).

If you have preferred suppliers or fabric codes, note them to reduce sourcing delays.

5. Include Colorways, Artwork, and Artwork Placement

If your design includes multiple color options or branding elements, specify them in detail:

Pantone codes for fabric colors.

Artwork placement diagrams (logos, patches, embroidery, heat transfers).

Print scale and exact positioning.

This prevents costly mistakes during sampling and production. Any artwork sent to the manufacturer should be at 100% scale and either an Illustrator or a PDF file with all fonts outlined.

6. Add a Measurement and Construction Sheet

For outerwear apparel, include a size spec sheet with measurements for each size (chest, waist, sleeve length, etc.). For backpacks, include dimensions (height, width, depth, strap length).

Indicate tolerances (acceptable deviation in measurements).

Highlight special construction methods (bonded seams, bartack reinforcements, box stitching).

The more precise your measurements, the less time is spent on corrections. For garments, the sizing chart is crucial, as it determines fabric and trim usage, and ultimately, the cost per unit. Most manufacturers will only produce the sample in one size and then use the sizing chart to estimate usage for the other sizes, unless specifically requested otherwise.

7. Note Functional and Performance Details

Backpacks and outerwear are functional products—small details matter. Document elements like:

Load-bearing capacity for backpacks.

Waterproof rating for jackets.

Ventilation systems or ergonomic adjustments.

Reinforced stress points.

This ensures the product performs as expected in real-world use.

8. Create a List of Materials

This list should include every component that goes into your product, down to the smallest detail. For example:

Zippers – YKK #8 water-repellent zipper, matte black.

Buckles – Duraflex 25mm side-release buckle.

Webbing – 25mm nylon webbing, black, matte finish.

This helps avoid ambiguity, ensures consistency, and streamlines the sourcing process. This list can also be created in collaboration with the manufacturer if you have not yet reached this stage in the design process. All manufacturers create these lists automatically as they produce your samples. This ensures that, as a manufacturer, we are ready to go the moment you place an order. Providing such a list to your manufacturer at the beginning speeds up the process of making the first sample.

9. Keep Your Tech Pack Organized and Professional

Use a consistent format (Excel, Adobe Illustrator, or specialized software).

Keep the file well-labeled and version-controlled to avoid confusion.

Include a cover page with your contact details, the date, and the version number.

An organized tech pack reduces misunderstandings and ensures everyone is working off the same document.

Detailed sketches with precise measurements are great for communicating with your manufacturer.

10. Use Prototype Images to Document Revisions

Once your manufacturer sends you the prototype, your feedback is critical in shaping the next version. The most effective way to communicate revisions is by using photos of the prototype with annotations:

Take pictures of the prototype from all relevant angles.

Use arrows, circles, or highlights to indicate areas that require changes.

Add written notes directly on or next to the photos explaining what should be adjusted.

Example: “Increase depth of main compartment by 2cm.”

Example: “Change chest pocket zipper to a waterproof zipper.”

Clearly separate must-change revisions from nice-to-have suggestions so the manufacturer knows how to prioritize.

This process makes your feedback actionable and reduces guesswork, ensuring the next prototype is much closer to your final vision.

11. Formats and Clarity: What Works Best for Manufacturers

Not all tech packs are equally effective. Here are a few important considerations:

Text-only tech packs are not ideal. While descriptions are helpful, visuals are critical. Without diagrams, images, or measurements, a text-only file often leads to misunderstandings.

Check manufacturer compatibility with file formats. Some factories may not be equipped to handle extremely complex or highly technical design software. Before sending, confirm that your manufacturer can open and interpret the file type you are using.

Hand-drawn sketches are acceptable but limited. If you prefer to sketch by hand, make sure you include detailed measurements and annotations. A simple sketch without scale or dimensions will not be enough for accurate sampling.

By selecting the appropriate format and incorporating both text and visuals, you enhance clarity and minimize delays.

12. Keep in Mind: Translation for Factory Teams

Many factories operate in regions where English (or your own language) is not the primary working language. This means:

Your tech pack will often be translated into the factory floor team’s language (e.g., Chinese, Vietnamese).

Ambiguous terms or vague descriptions may get lost in translation.

The more transparent and more precise your notes, the easier it is for your manufacturer to translate without errors.

Think of your tech pack as an instruction manual: the more straightforward, structured, and direct it is, the easier it will be to produce your product exactly as intended.

13. Best Practices vs. Strict Rules

It’s essential to note that these points, which we have listed here, are best practices rather than hard-and-fast rules. A well-prepared tech pack is a powerful tool; however, manufacturers are experienced in working with various types of briefs, sketches, and samples. Even if you can’t implement every point mentioned here, a good manufacturer will still be able to interpret your needs and deliver the correct product.

The goal of these guidelines is to streamline the process and make it faster, not to create unnecessary barriers. Think of them as tools to help reduce revisions, improve communication, and speed up development, not requirements you must meet perfectly every time.

Final Thoughts: Tech Packs Build Better Partnerships

A complete, accurate tech pack not only saves time for your manufacturer, it also saves you, the client, money and frustration. With fewer rounds of revisions and a faster sampling process, your product can move to production smoothly and efficiently.

At Kowide Outdoors, we encourage clients to invest the time in preparing a thorough tech pack. It’s the foundation of a successful collaboration, ensuring that your backpack or outerwear design is brought to life exactly as you envisioned.

KOWIDE OUTDOORS – Who We Are

We are a Bespoke Backpack and Outdoor Apparel Manufacturer from Taiwan

A leading OEM manufacturer with over 50 years of experience supplying products to world-renowned brands across Europe, Asia, Australia, and North America. Our world-class production facility in Vietnam, situated within easy reach of Ho Chi Minh City, is ideally suited to cover all manufacturing needs, from R&D, sourcing, and prototyping to bulk production.

Through technical expertise, ethical management, and rigorous quality control, Kowide Outdoors consistently strives to exceed client expectations, taking pride in helping clients achieve success by delivering the highest level of quality and unparalleled customer service.